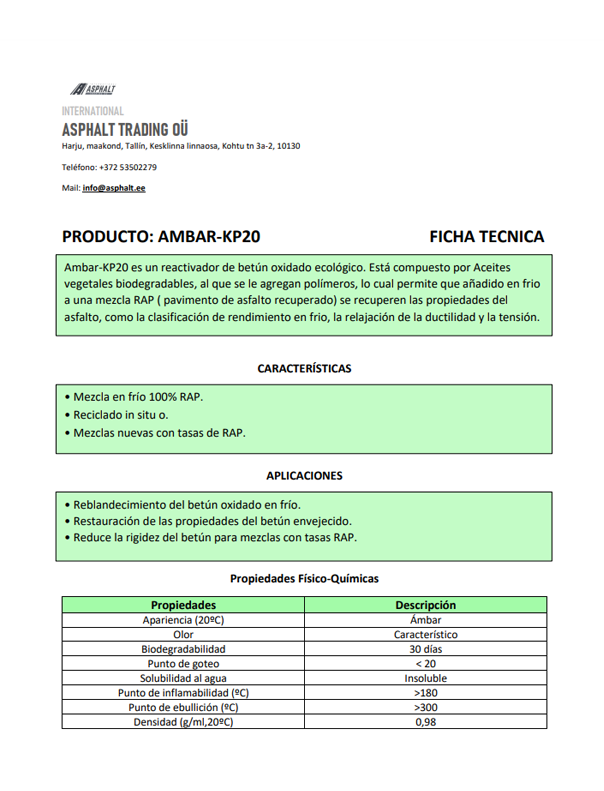

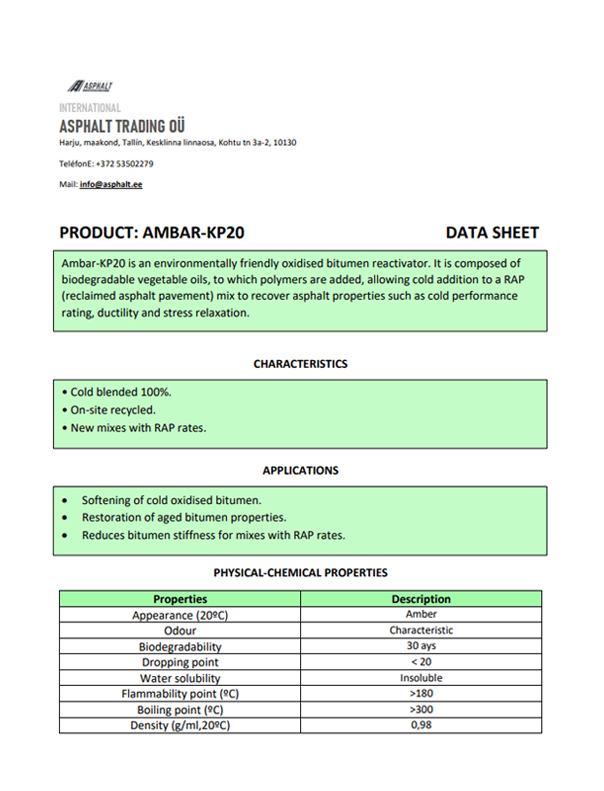

AMBAR KP-20

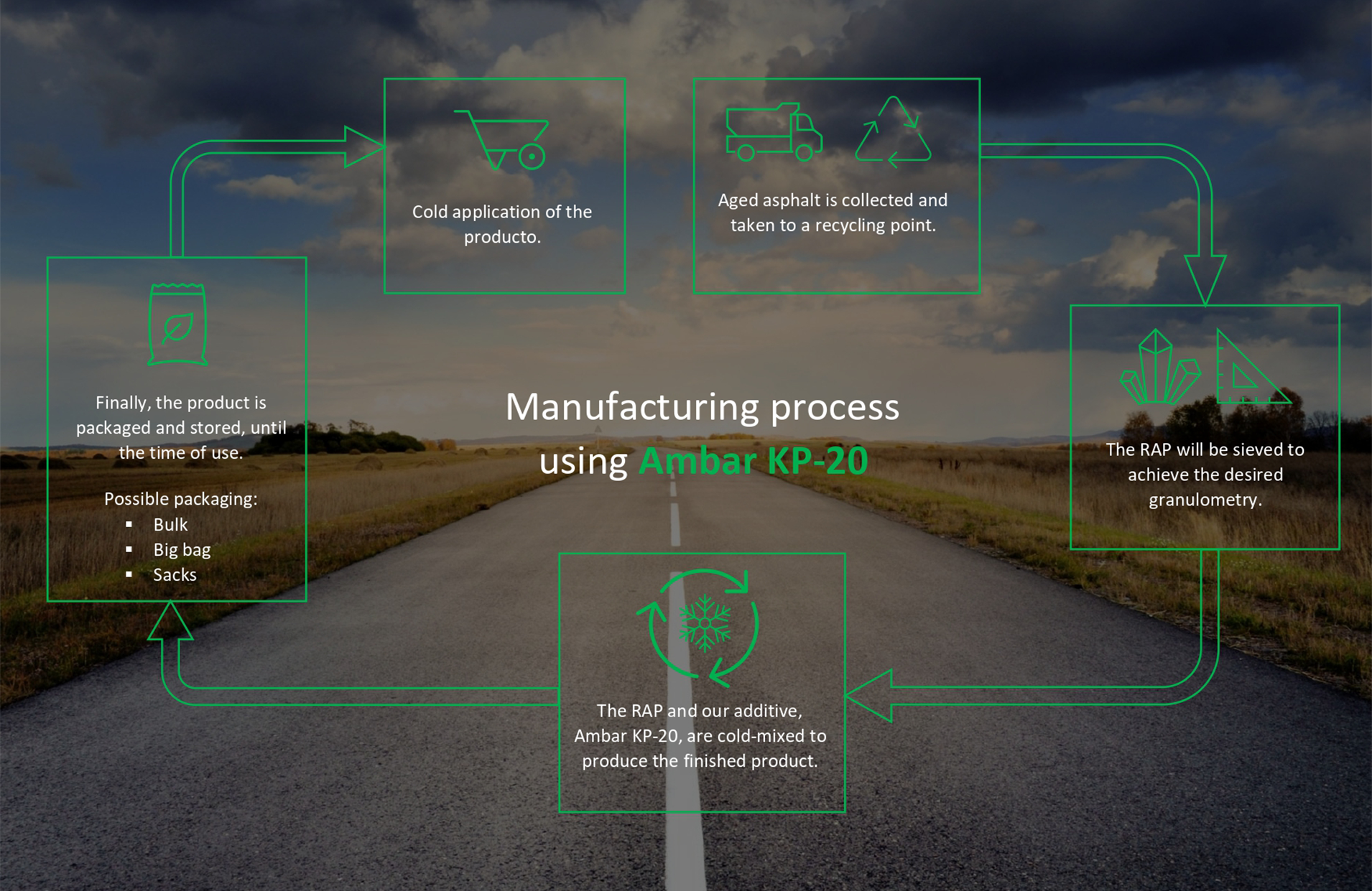

Our oxidised bitumen reactivator is composed of ecological materials, which allow that when added cold to a RAP mix (Recovered Asphalt Pavement), the properties of the asphalt are recovered, as well as its cold performance, ductility and tension relaxation.

Ambar KP-20 is mixed 100% on cold and dry RAP, restoring part of the properties lost due to ageing. In this way, a valuable raw material is recovered to give it a new useful life (patching and rehabilitation of affected services), preventing its end-of-cycle from ending up in landfills.

Ambar KP-20 allows asphalt to be stored for 24 months without compromising its performance.

Advantages

COMPARED TO OTHER ASPHALTS

Ambar-KP20

Bitumen reactivating additive

Our additive Ambar KP-20, allows you to reactivate the lost properties of aged asphalt to give it a new useful life.

the additivation with Ambar KP-20 is 100% cold, so it does not produce greenhouse gases.

Ambar KP-20 facilites application, compaction and improves mat density with fewer roller passes on additivated RAP (reclaimed asphalt pavement).

Immediate return of traffic, thus reducing delays for users.

Additivate with Ambar KP-20 gives these results

Environmentally friendly

Environmentally friendly

Lower costs

Lower costs

Recycle of raw materials

Recycle of raw materials

Lower risk

Lower risk

How do our products work?

THE STEP-BY-STEP PROCESS

Step 1

Add the additive into the dry milled material.

Step 3

Apply or store ready for use.

Step 2

Mix in cold until a homogeneous composition is obtained.

Step 4

Transport to the application site.

Step 1

Add the additive into the dry milled material.

Step 2

Mix in cold until a homogeneous composition is obtained.

Step 3

Apply or store ready for use.

Step 4

Transport to the application site.