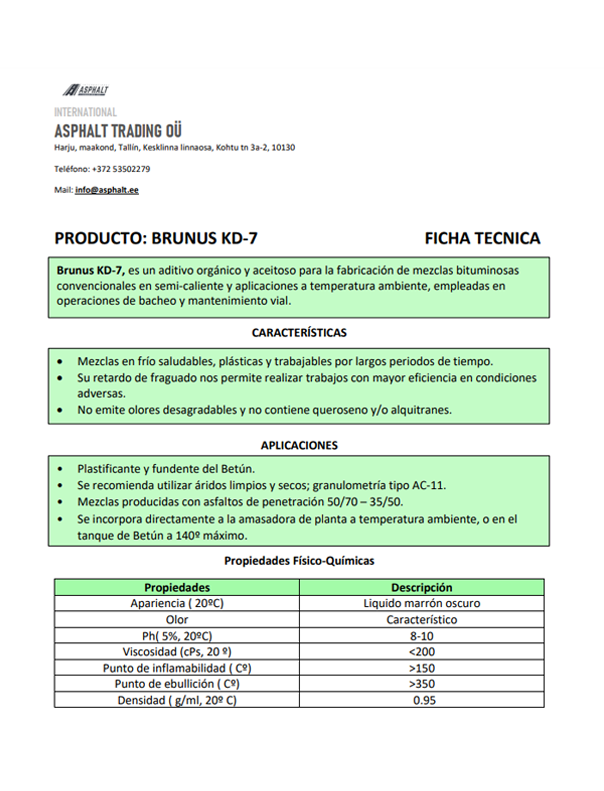

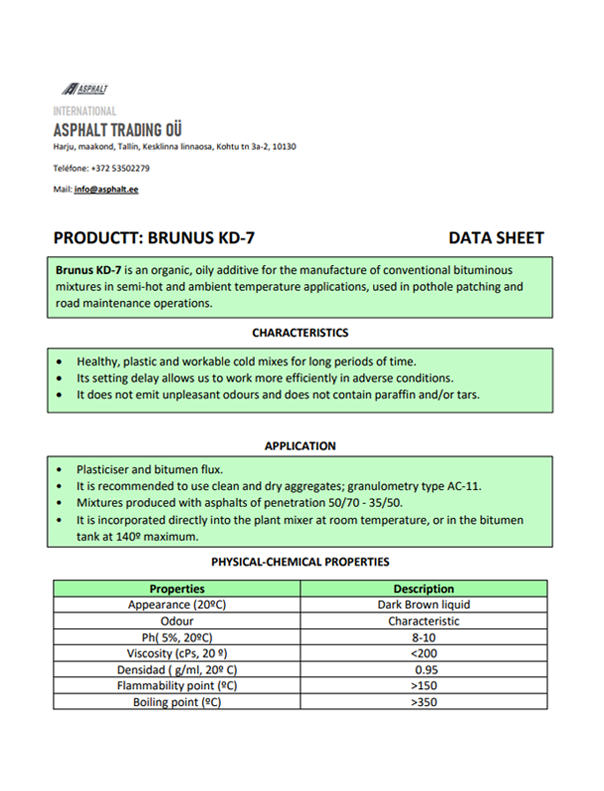

BRUNUS KD-7

Brunus KD-7 is an organic additive for the production of semi-hot asphalts with cold application. It is manufactured at 110ºC - 130ºC, resulting in significant energy savings.

Brunus KD-7 guarantees healthy, plastic and workable mixes for long periods of time and can be packaged. The surplus asphalt can be stored again, so that it can be used for other maintenance work, which leads to a total reduction of waste material.

Brunus KD-7 does not emit odors and does not contain kerosene or tars.

Thanks to its delayed setting time, it allows us to work more efficiently in adverse conditions.

Advantages

COMPARED TO OTHER ASPHALTS

Brunus KD-7

Hot asphalt for cold application

Our Brunus KD-7 additive allows you to produce a hot asphalt,

capable of being applied cold.

Asphalt manufacturing with Brunus KD-7 is between 110ºC - 130ºC, so it consumes less energy and produces fewer greenhouse gases.

Workable in areas with extreme, changing or adverse climates.

Immediate return of traffic, reducing delays for users.

Adding Brunus KD-7 provides these results

LOWER RISK

LOWER RISK

LESS ENERGY EXPENDITURE

LESS ENERGY EXPENDITURE

EASY WORKABILITY

EASY WORKABILITY

STORABLE (+2 YEARS)

STORABLE (+2 YEARS)

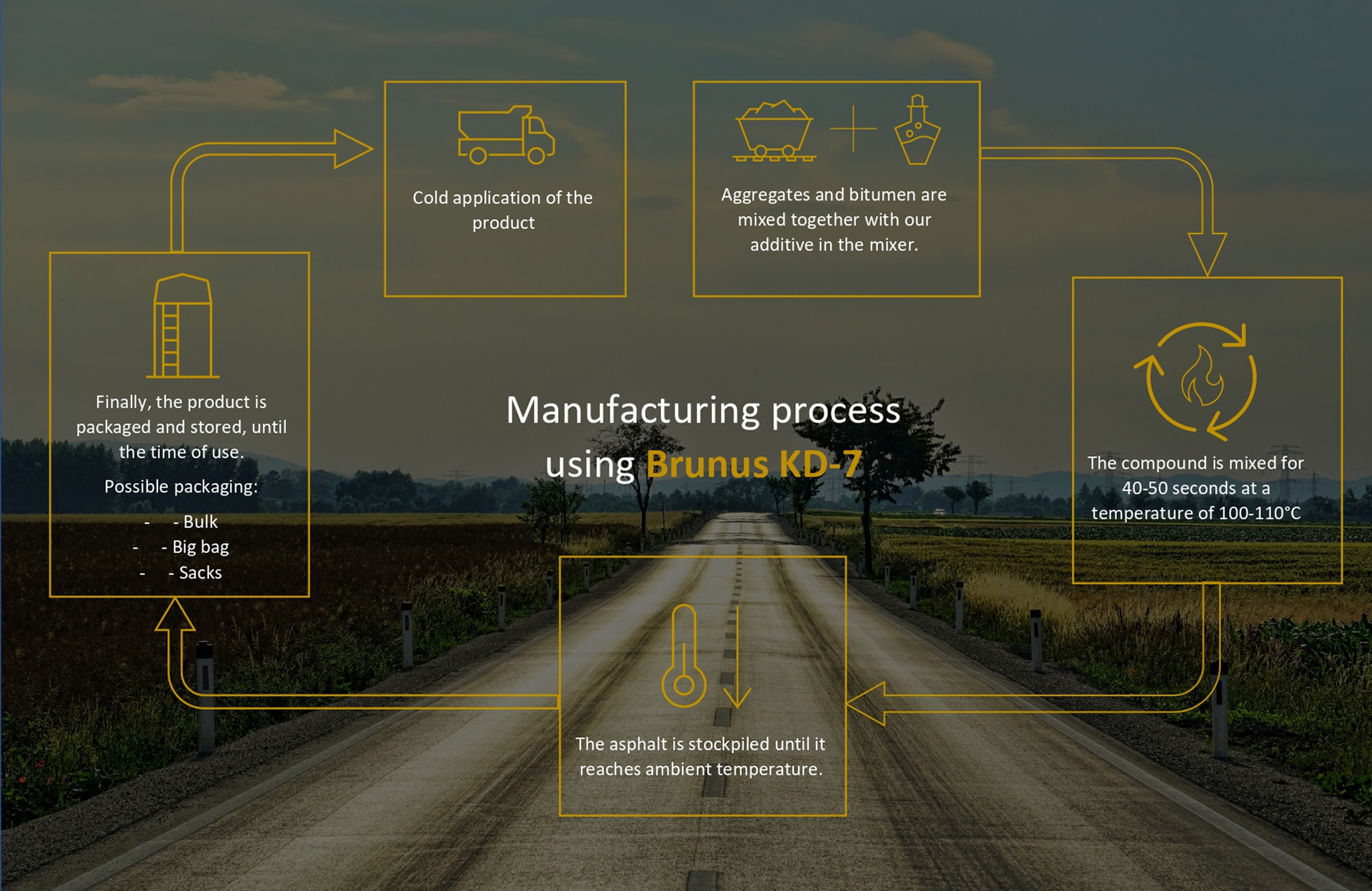

How do our products work?

THE STEP-BY-STEP PROCESS

Step 1

Add the additive to the bitumen tank.

Step 3

Add the composition to the mixer.

Paso 5

Ready for bagging or application.

Paso 2

Recirculate the additive together with the bitumen.

Paso 4

Stockpile the asphalt until it reaches room temperature.

Step 1

Add the additive to the bitumen tank.

Step 2

Recirculate the additive together with the bitumen.

Step 3

Add the composition to the mixer.

Step 4

Stockpile the asphalt until it reaches room temperature.

Step 5

Ready for bagging or application.